From Scheduling to field execution: digitise your maintenance in SAP

Discover how you can increase your asset uptime by improving your work planning & scheduling, field execution and real-time evaluation of your performance directly in SAP.

Ready4 Asset Management (R4AM) has been designed to industrialise and automate your maintenance processes. It gives you a real-time 360-degree on your entire data flow across all your SAP systems. From instant notification creation and alerts to work order management, master data, planning, scheduling and execution, each process is simplified and intuitive.

View the Maintenance Flow covered by R4AM

Supporting your maintenance and field service challenges from delivery to improvement and enhanced performance has always been a challenge, both logistically and financially.

Capitalising on a bi-directional connector, preventing your critical data from being manipulated, extracted or stored in another database, we guarantee SAP will be the sole repository for your proprietary data.

We have a fully integrated platform to digitally transform your maintenance and field service operations. Ready4 Asset Management will help prioritise and align the right maintenance activity at the right time with the right people, ensuring you to maximise the assets availability.

How accurately and quickly you capture incidents in the field and report them to your maintenance teams is key. But frequently work requests are not matched to the right assets and the maintenance required is incorrectly described. Sometimes there can be several reports from different people on the same issue increasing workload and duplicating effort, or at other times the problem is forgotten and not reported at all.

Ready4 Asset Management gives you an intuitive and easy-to-use mobile application that allows you to create the fields you need, scan or use OCT to identify each asset and upload photos. You will get instant access to all pending and historic data about your asset and be able to add incident and damage coding to structure each work request.

The gatekeeping process allows you to assess, evaluate, prioritise and validate your work requests. Ready4 Asset Management puts checks in so that you can link your work request with the validation of the work before it commences.

The planning and preparation stage is key to every intervention and potential escalation and ensures your technicians and engineers are empowered with the key information from the outset to complete each assigned work order, saving a lot of time.

With Ready4 Asset Management your work is precisely defined in the right fields so that the maintenance order and prerequisites are accurate, and the right labour, parts and tooling resources are allocated. Any relevant documentation can easily be added to the work order to assist the technician in doing their job.

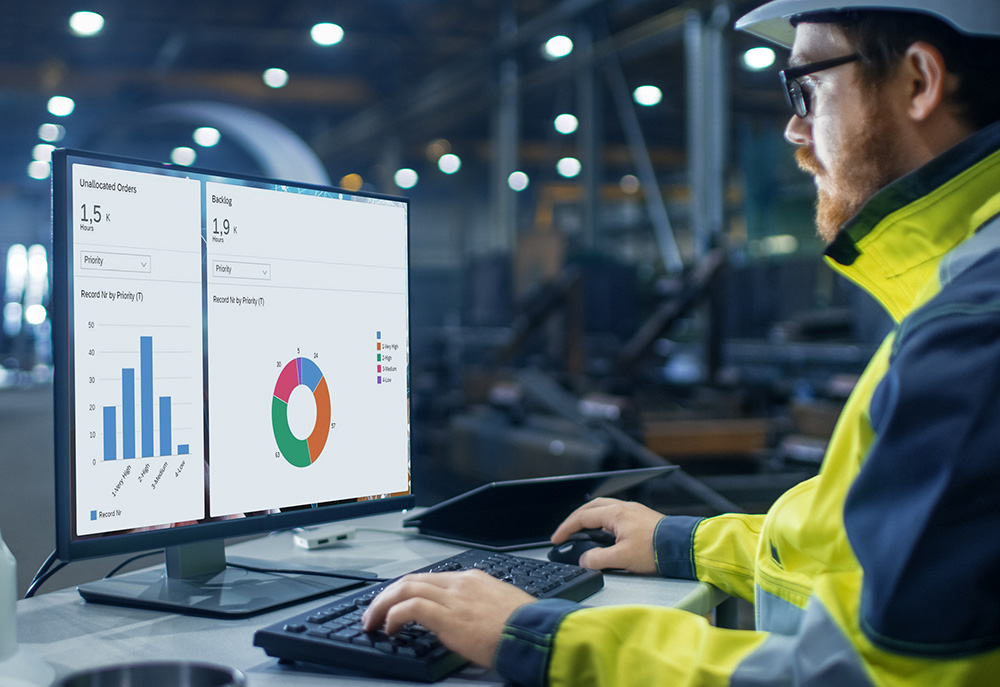

Get a clear view on all your maintenance activity & workload, including pending work orders, overdue and any backlog Avoid capacity issues by ensuring all tools, equipment, workforce and spare parts are allocated and available. Monitor the maintenance window vs. your estimate work order execution timeframe.

Technicians can easily access their daily and weekly workloads and priority scheduling, with online/offline access as required. The management dashboards enable senior leaders to easily see comparisons for forecast versus actual maintenance.

Sign-off is an important part of the process in maintenance and field service. With the platform you can assess each work order with a formal validation and sign-off process for quality control, deliverables and specific accountability. Sub-contractors should also be included in the sign-off process.

As a Technical Asset Manager, you have responsibility for the management of your organisation’s asset portfolio. These responsibilities usually cover many areas, from overall portfolio management and health monitoring through to controlling maintenance costs and maximising availability and providing insight to the schedulers and planners. Without IoT processes in place as well as the right software tools and a centralised assets database, it will be very hard to optimise your assets, manage their availability, link to failure and causes and control maintenance costs. It is therefore vital to have 360-degree view of your asset management performance to give you all the information you need on one simplified platform where you can monitor all aspects of your assets and act and respond as needs change.

We’ve developed a dedicated Asset Dashboard so you can combine available Master Data from your ERP system and your IoT sensors readings from any SAP backend solution. This integrated approach allows you to consolidate your assets through one single dashboard which is easy to use and implementable in a plug & plan mode, meaning there’s no need for a large product roll-out, keeping costs down. Your combined data is displayed on the main cockpit screen showing the Overall Equipment Efficiency (OEE), and at-a-glance, stats such as maintenance costs, assets under repair, assets by type etc. You can also access more detailed data about asset types, maintenance required or repairs. You will also get IoT data readings allowing you to measure the health of your assets on an ongoing basis.

The dashboard gives you a combined view of the status of your assets and lets you set parameters such as temperature thresholds and monitor KPIs for efficiency and effectiveness. You’ll get in-depth analysis of technical data and operational data all in one place, helping you to produce maintenance and repair strategies more easily and quickly. As we are proposing a platform with a full end to end functional coverage regarding your maintenance plan, you will be able from this cockpit to generate automatically alerts & notifications, generating workload into the Gatekeeping interface, where all those alerts & notifications will be centrally managed and eventually transformed into a Service Order or Work Order.

Asset management refers to the management of various types of assets, such as physical assets, financial assets, and intellectual property. The terms...

When implementing SAP PM (Plant Maintenance), there are various "do's" and "don'ts" to consider in order to enhance the success of the...

What is AI (Artificial Intelligence)?

AI, or artificial intelligence, refers to the development of computer systems that can perform tasks that...